Diaphragm Walls

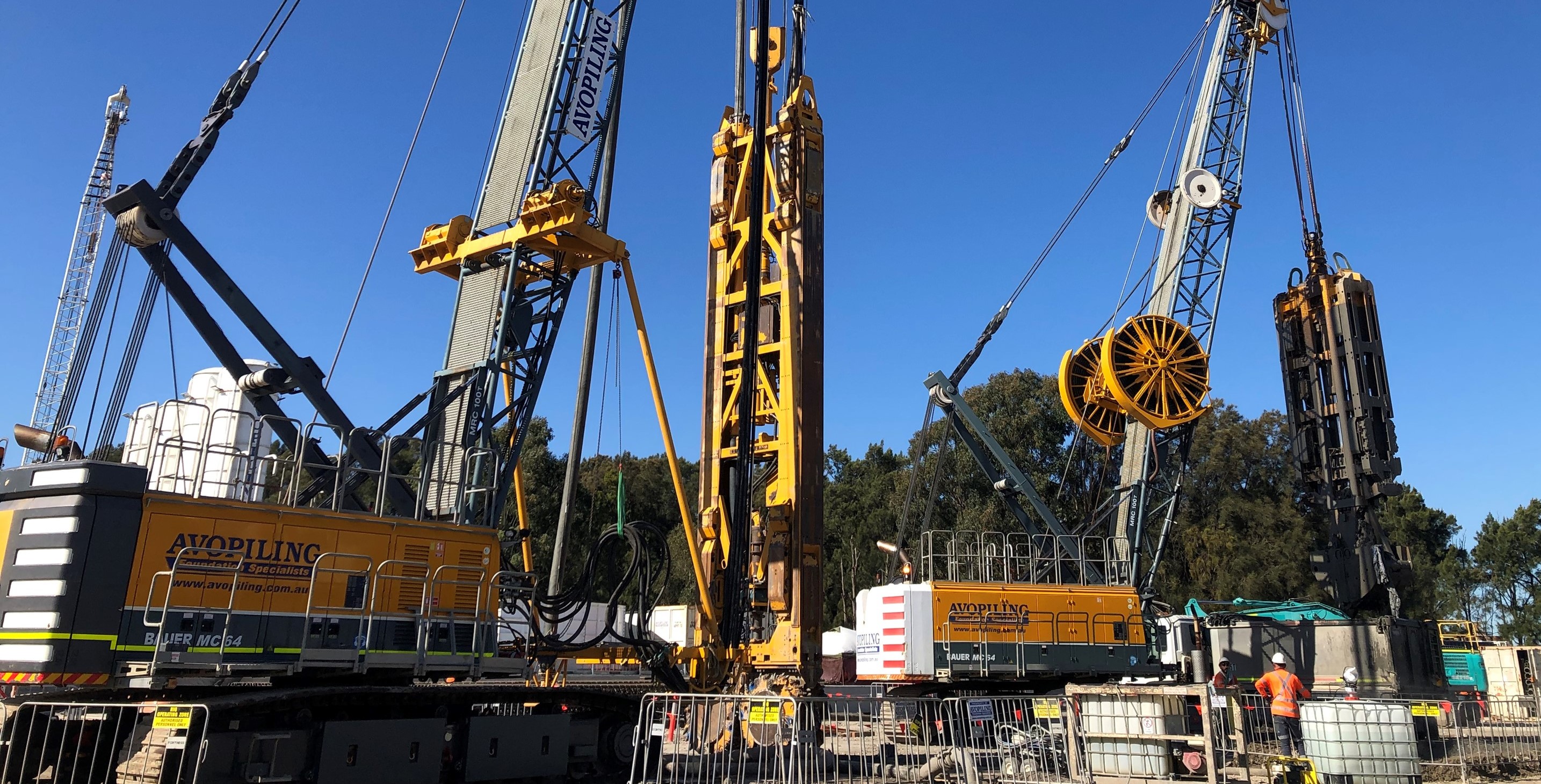

Another form of retaining wall is the diaphragm wall system.

Trench thickness from 600mm to 1500mm by 2800mm long.

Trench depth up to 75 metres using 150 tonne to 170 tonne rig working capacity

Applications

The most popular use of a diaphragm wall is for the construction of multilevel basements and for top –down building construction method. The trenching process of this diaphragm wall system is aided by bentonite fluid support. During the excavation process bentonite is introduced and recycled during the construction process. Bentonite is used during the excavation process to facilitate the removal of the cuttings when using the trench cutter, until reaching desired depth. This is later replaced by placing concrete in the trench via the tremie method. Bentonite is returned to holding tanks on site to undergo treatment and reuse.

The diaphragm wall system is a fantastic solution compared to any other conventional retaining wall systems because of increased water tightness by minimizing vertical joints. The use of the diaphragm wall system is to alleviate issues in constructing underground tunnels along heavy public presence, deep basements without endangering the stability of the foundations of the nearby buildings. Diaphragm wall system can be applied to water storage, sewage disposal shafts, security vaults, pits, and wharves, containment of contaminated area and control of toxic effluents travelling underground.

Diaphragm wall ancillary structure comprises of de-sanding equipment, silos, holding tanks, transfer pumps, mixer tanks and compressors.

Advantages

- Ideal for top down construction projects.

- Can be installed in virtually all soil conditions including high strength rock.

- Reduced noise and vibration compared with other shoring techniques such as sheet piling.

- Very accurate method of construction with high tolerance levels.

- Removes the requirement for dewatering the site.

- Can be used in the immediate vicinity of existing buildings.

- Can be designed to carry structural loads thereby reducing the foundation costs.

5-7 Charles Street Parramatta DWall

Project Outline

Scope of Works

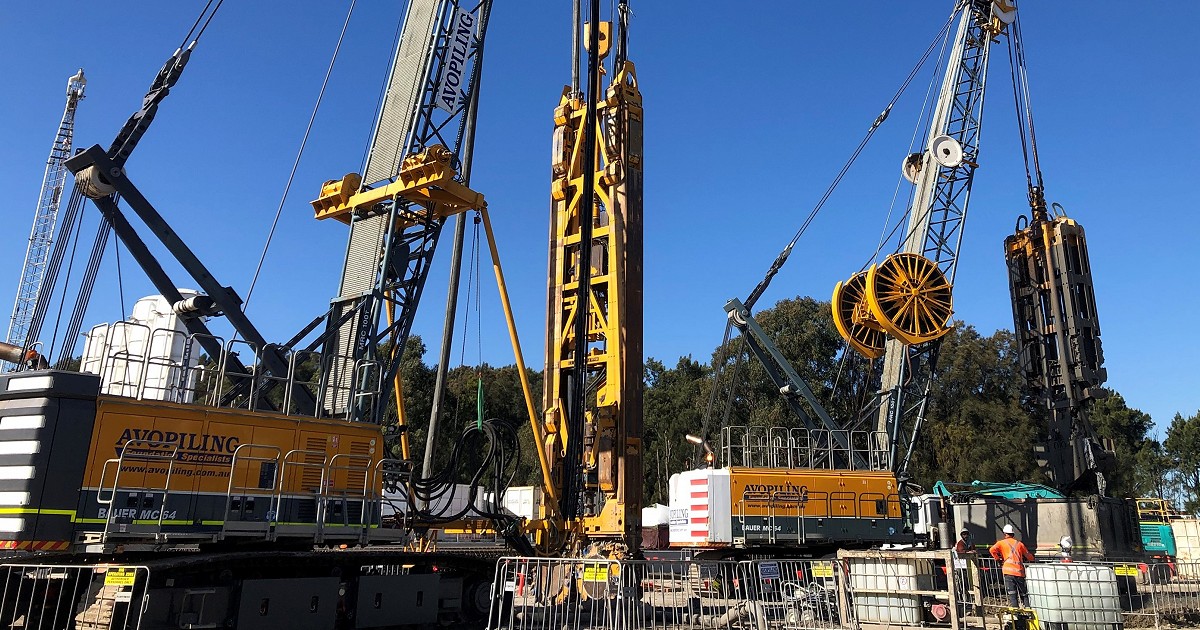

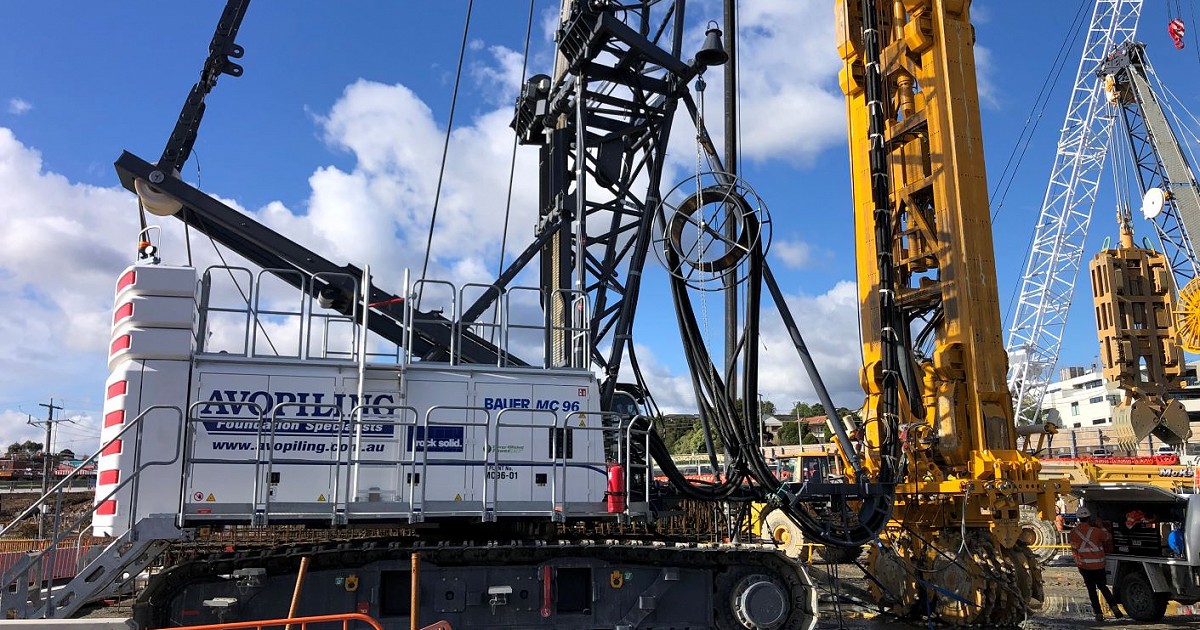

M6 Stage 1 C2 Shaft and Cut and Cover

Project Outline

Scope of Works

Diaphragm Wall Project at Melbourne Victoria Australia

Project Outline

Products / Services

Diaphragm WallsScope of Works

Project examples

Project examples

M6 Stage 1 C2 Shaft and Cut and Cover

Project examples

Diaphragm Wall Project at Melbourne Victoria Australia

Would you like more information? Enquire

Other products & services

Industry leading techniques and equipment